Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Metal Separator-Vibrating Sreening-copy

-

USD 2,708.00 ~ USD 3,000.00/unit

1/ unit (Min. Order)

Introducing our Metal Separator—Vibrating Screening—copy, a cutting-edge solution for efficient metal separation in various industries. Designed with precision, this innovative equipment utilizes advanced vibrating screening technology to swiftly and accurately separate metal contaminants from materials, ensuring product purity and integrity. Enhance your production process with our reliable metal separator-vibrating screening copy.

Metal separator acts to detect and separate all metals mixed in plastic materials, including iron and non-ferrous metals (such as copper, aluminum, stainless steel). Since metal impurities are mixed in the process of crushing and recycling the old materials, accidents are eventually entered into the production, which increases the number of shutdown maintenance, which leads to an increase in cost and affects production efficiency.

In the plastics industry, in order to reduce the number of down times, increase production efficiency, and reduce maintenance and repair costs, metal separators must be used in the plastic material processing.

FEATURES

◆ Quickly separate various metals such as steel, copper, aluminum, stainless steel, etc.

◆ Metal particles as small as 0.4 mm or long wires can also be separated.

◆ Directly installed on production equipment (such as injection molding machine), multiple protections to prevent metal particles from damaging equipment

◆Simple to use and install

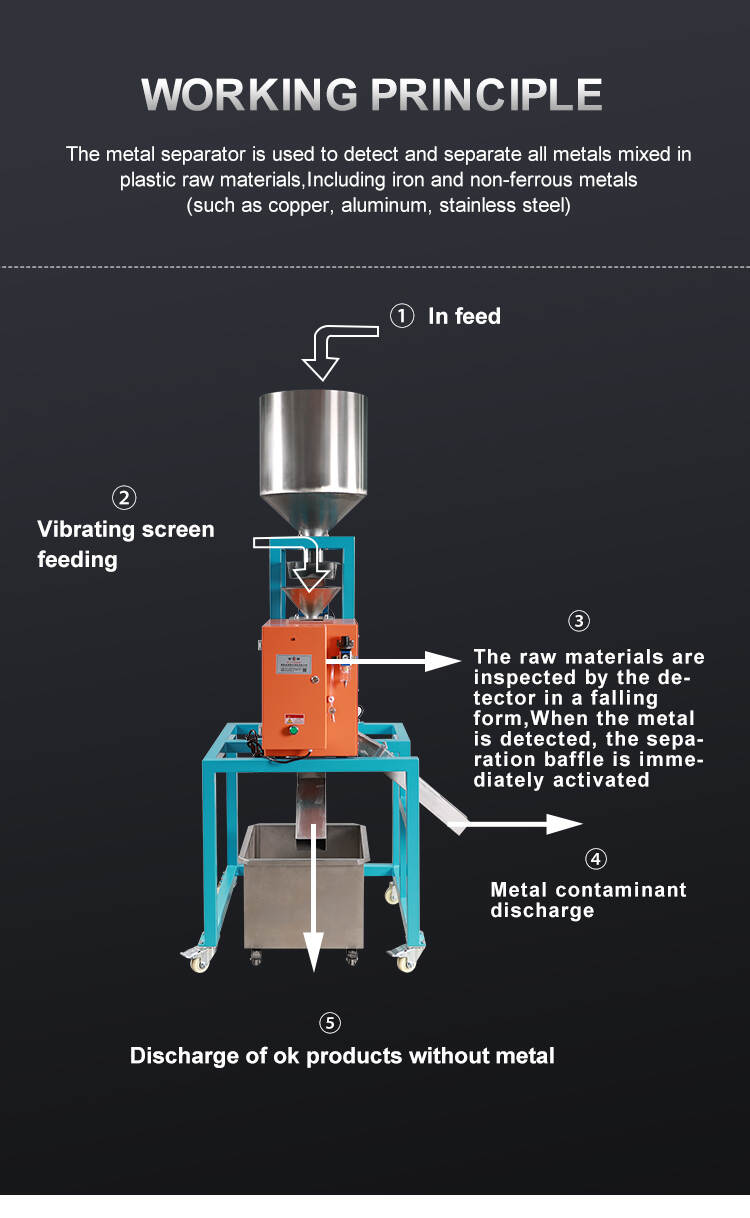

PRINCIPLE

The raw material is freely dropped from the hopper or feeder through the metal separator. If there is no metal impurity, the raw material will pass directly through the metal separator to the sensing tank. If the detector detects metal in the raw material, the diverter valve will act. With metal and a small part of the raw material, the splitter plate quickly returns to the normal position, the speed of the manifold is adjustable, and the precision of the induction is adjustable according to the production needs, even metal particles as small as 0.4MM can be detected and separated.

WHY METAL SEPARATOR

◆ Improve production efficiency

◆ Improve raw material utilization

◆ Improve product quality

◆Reduce equipment maintenance costs

◆Protection to other production equipment:

-Damage screw

-Clog nozzle, mold flow path (hot runner)

-Increase hot runner pressure, causing plastic flow block

-Metal scratch mold

-The finished product contains metal, resulting in short circuit and no insulation

-Scratch the finished surface